HYGHSPIN - twin screw pump for the beverage industry

With high performance but also gentle processing, our pumps have no difficulties with various products from syrup through to yeast and up to and including frozen fruit concentrates.

Beverages

- Fruit concentrates, possibly frozen

- Juices with fruit pieces

- Syrup

- Liquid sugar

- Wine / cognac / sparkling wine / liqueurs

Application examples

| Application range | Volume flow | Pressure differential | Product |

|---|---|---|---|

| Orange juice with fruit pulp | 4 m³/h | 1 bar | HYGHSPIN 50 |

|

Frozen juice concentrate |

95 m³/h 20 m³/h |

12 bar 12 bar |

HYGHSPIN 125 HYGHSPIN 90 |

| Liquid sugar | 10 m³/h | 10 bar | HYGHSPIN 70 Mobile |

| Eggnog | 2 m³/h | 2 bar | HYGHSPIN 70 |

Advantages:

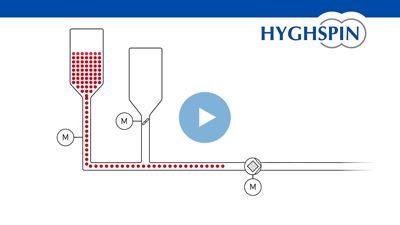

- Excellent NPSH values, high volume flows without cavitation

- High flexibility, wide operating range for different products, utilisation as a CIP conveying pump

- Very gentle and smooth conveyance, no spinning of products

- Excellent hygiene standards, pumps are CIP and SIP capable,

- Safe-to-run dry pumps without rinsing the shaft seal for mobile pumps or frozen fruit concentrates

Breweries

- Yeast

- Brewer´s grain

- Syrup / concentrates

Application examples

| Application range | Volume flow | Pressure differential | Product |

|---|---|---|---|

| Yeast |

43 m³/h 3 m³/h |

3 bar 2 bar |

HYGHSPIN 90 HYGHSPIN 50 |

| Syrup | 12 m³/h | 6 bar | HYGHSPIN 70 |

| Brewer´s grain | 10 m³/h | 8 bar | HYGHSPIN 90 Hopper |

Advantages:

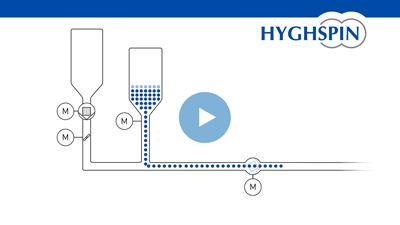

- Very gentle and uniform conveyance with low conveying speeds

- Excellent hygiene standards, pumps are CIP and SIP capable

- Flexibility, wide operating range, utilisation as a CIP conveying pump

- Extruder function of the HYGHSPIN Hopper for non free-flowing media

- Wear-resistant designs for abrasive media