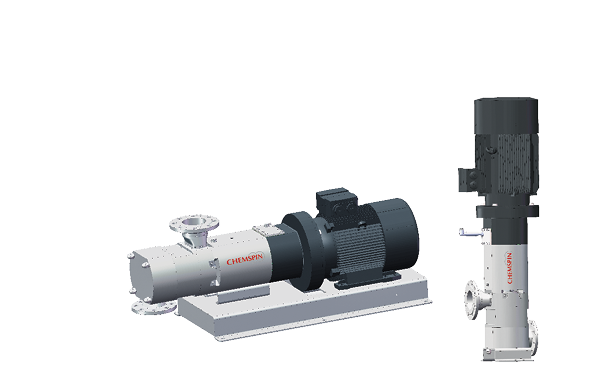

CHEMSPIN INLINE – choice of couplings for simple change to twin-screw pumps

CHEMSPIN twin-screw pumps are available with different coupling orientations. INLINE versions with parallel couplings are available for pipes with continuously vertical or horizontal runs.

These versions permit simple replacement of rotary lobe or rotary piston pumps with CHEMSPIN twin-screw pumps.

CHEMSPIN twin-screw pumps can be mounted

• horizontally

• vertically upwards or downwards

• sideways to a wall

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse