Twin-screw pumps from the HYGHSPIN series are the perfect solutions for countless applications

Innovative and hygienic design, highly economical, optimum MTTR value – main reasons for HYGHSPIN.

The HYGHSPIN stainless steel pump series from Jung Process Systems have been proved worldwide and can be used for flowable products with practically all viscosities and consistencies – whether aqueous, highly viscous, lumpy, fibrous, or gas-laden.

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse

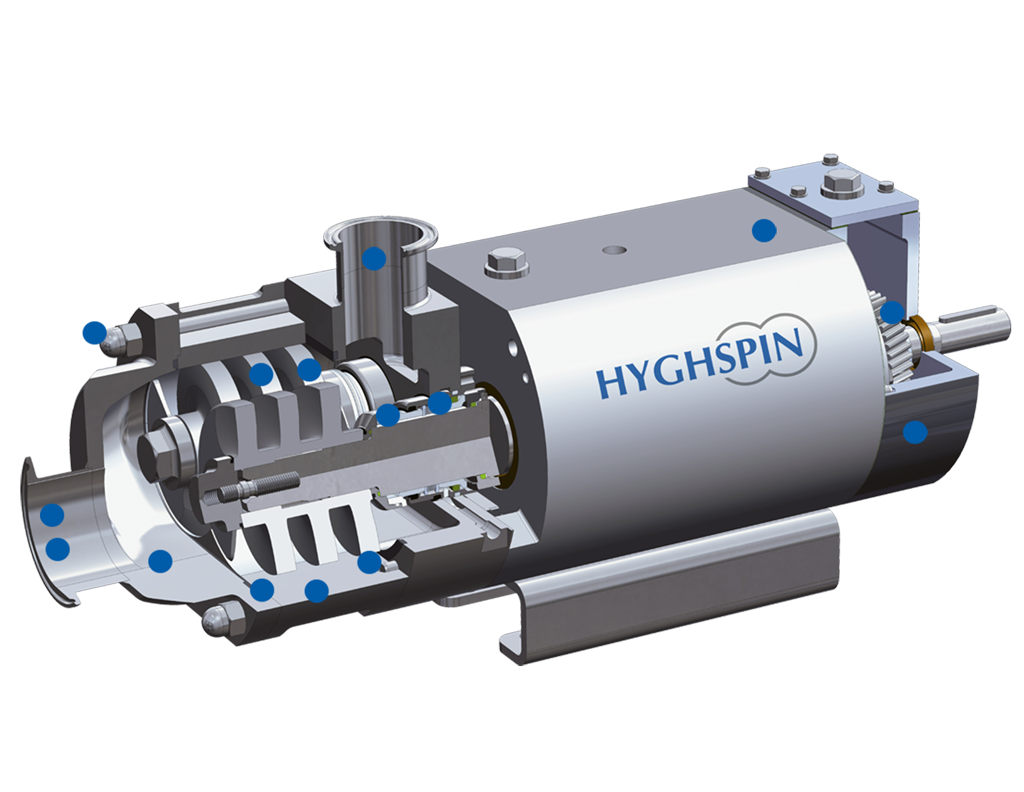

HYGHSPIN Extended twin-screw pump – the smart solution for low-pressure applications

High throughputs and large solids with compact dimensions

The HYGHSPIN Extended is one version of the worldwide proven HYGHSPIN pump series made of high-grade stainless steel. With the HYGHSPIN Extended, focus lies on applications in the low-pressure range, with pressure differences up to 6 bar.

Screws and pump housing have been lengthened. This extends the application possibilities in terms of individual pump sizes with higher volume flows or particularly large solids.

The HYGHSPIN Extended stands for high performance with compact dimensions. It is available in modular form or with free shaft end,

and comes in sizes of 50, 70, 90, 105 and 125. Max. pumping volume is about 350 m³/h. Delivery pressure is up to 6 bar.