Twin-screw pumps from the HYGHSPIN series are the perfect solutions for countless applications

Innovative and hygienic design, highly economical, optimum MTTR value – main reasons for HYGHSPIN.

The HYGHSPIN stainless steel pump series from Jung Process Systems have been proved worldwide and can be used for flowable products with practically all viscosities and consistencies – whether aqueous, highly viscous, lumpy, fibrous, or gas-laden.

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse

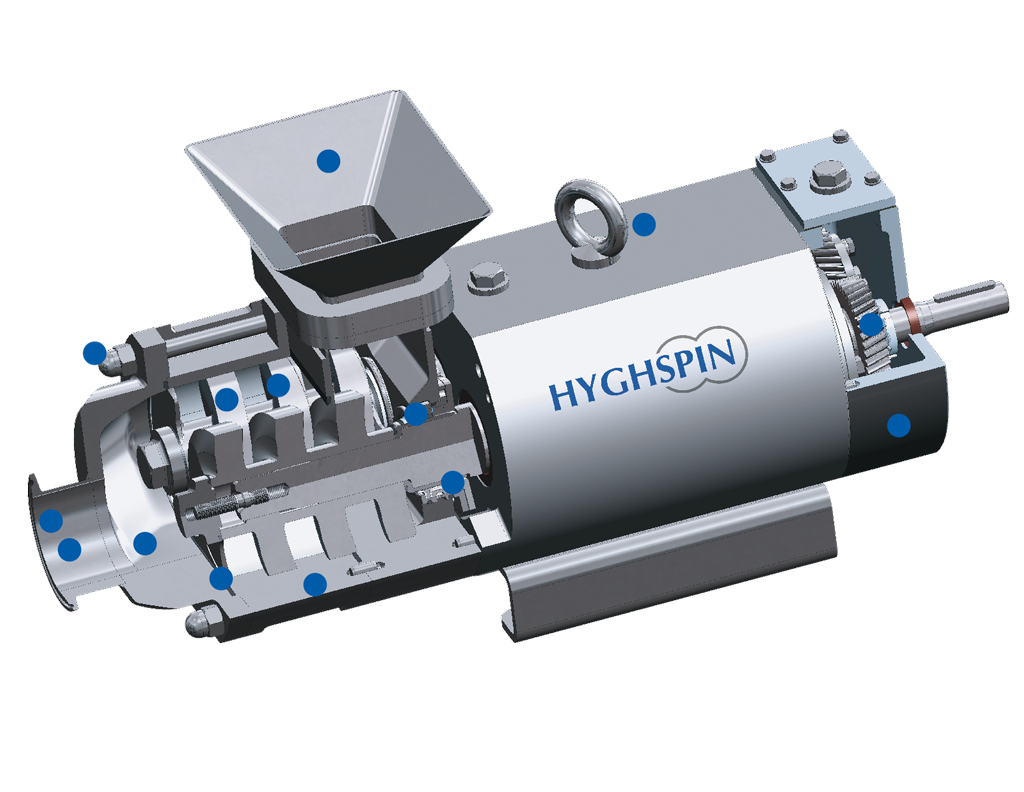

HYGHSPIN Hopper twin-screw pump – the efficient solution for non-flowable products

Hygienic, gentle, economic

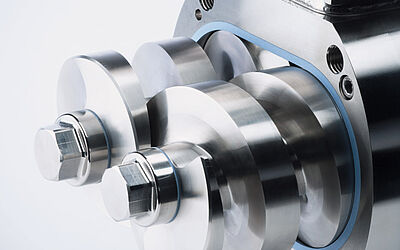

The HYGHSPIN Hopper is an addition to the worldwide proven stainless steel HYGHSPIN series. The innovative twin-screw pump with hopper opening is able to handle products with a viscosity of up to 1000 mPa·s without problems. Its screws are extended, so that non-flowable products are drawn in below the hopper opening (like an extruder) and fed to the pump chamber. This ensures particularly gentle product transport – external extruders can be eliminated completely.

Consequently, the HYGHSPIN Hopper represents a very attractive 3-in-1 solution: Infeed, conveying, and cleaning are carried out in a single unit. It is available in modular form or with free shaft end,

and comes in sizes of 70, 90, 105 and 125. Max. pumping volume is about 20 m³/h. In the standard version, the pressure difference is max. 10 bar. Optionally, up to 25 bar are possible.