The universal solution for diverse pumped media

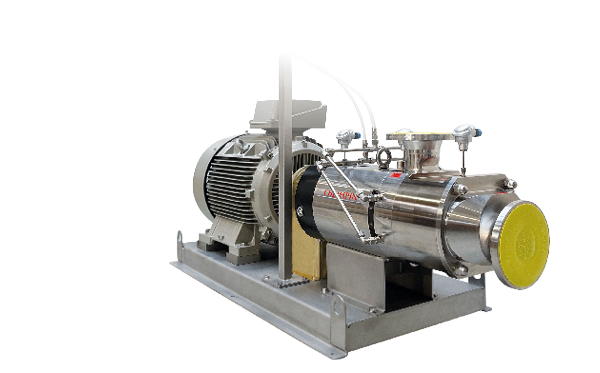

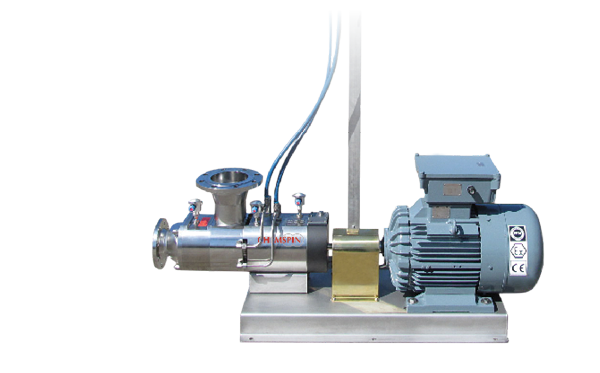

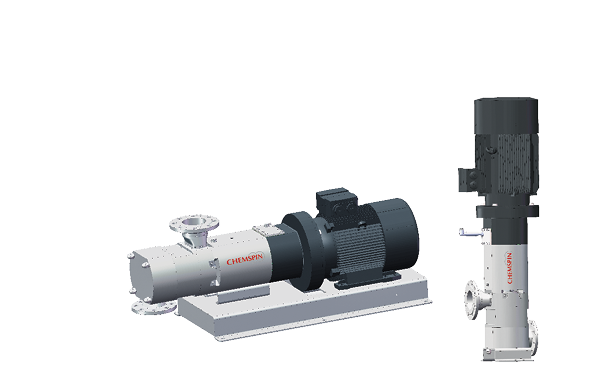

Whether aqueous, highly viscous, lumpy, fibrous, corrosive, abrasive or gas-laden – the CHEMSPIN series of high-grade stainless steel pumps is suitable for media of virtually any consistency, thereby featuring utmost efficiency.

The particularly service-friendly twin screw pump convinces with a very high suction capacity and gentle conveyance of all products. Self-priming, and able to handle entrained gas, they ensure fast and safe medium transfer. For non-free flowing media, use of the CHEMSPIN ES is recommended.

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse