Twin-screw pumps from the HYGHSPIN series are the perfect solutions for countless applications

Innovative and hygienic design, highly economical, optimum MTTR value – main reasons for HYGHSPIN.

The HYGHSPIN stainless steel pump series from Jung Process Systems have been proved worldwide and can be used for flowable products with practically all viscosities and consistencies – whether aqueous, highly viscous, lumpy, fibrous, or gas-laden.

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse

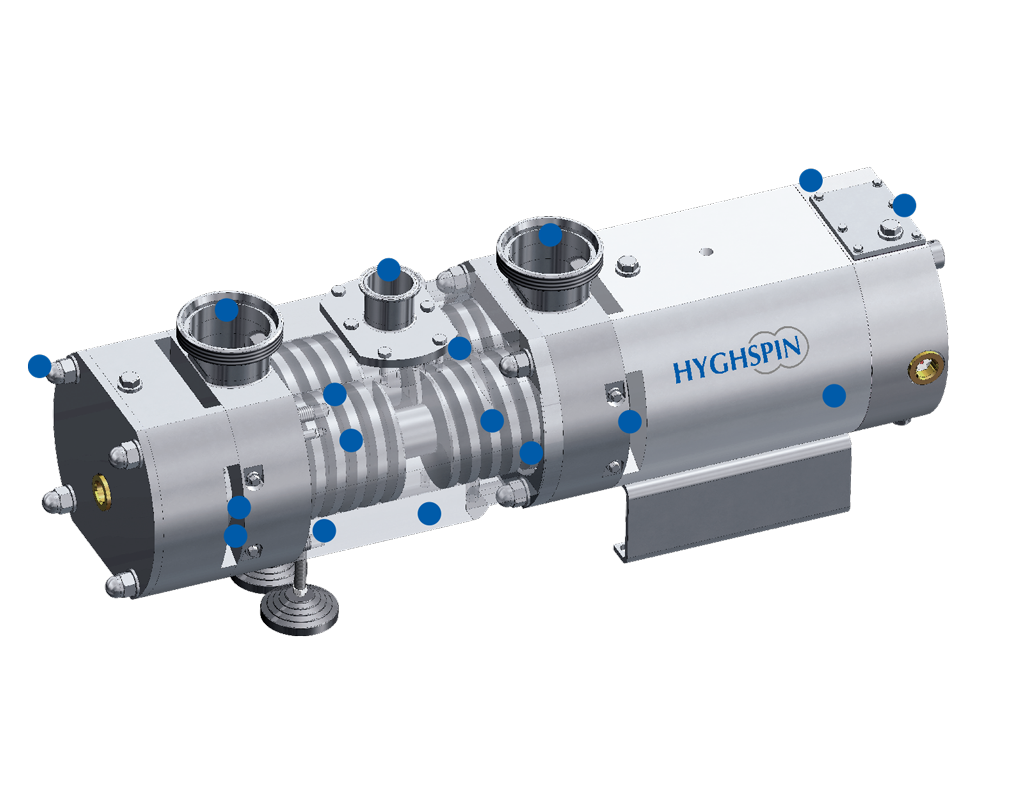

HYGHSPIN Double Flow twin-screw pump – the efficient solution for high pressures

Double-flow, hygienic, high performance

The HYGHSPIN Double Flow extends the application range of the HYGHSPIN series, with high pressure differences up to 50 bar. This permits the HYGHSPIN advantages to be used also in high-pressure applications.

The HYGHSPIN Double Flow is a double-flow stainless steel twin-screw pump. It is fitted with two external inlet connections and one central outlet connection. Bearings on both ends keep shaft deflection under control. The high pressures due to axial thrust are compensated internally. Shaft seals are arranged on the suction side. In spite of the high pressure differences, all the main components are not subjected to high loads, which results in high reliability and outstanding service life. Moreover, the parallel use of two stages opens up the possibility for high volume flows.

The HYGHSPIN Double Flow is the hygienic and gentle solution for high-pressure applications.

Optionally, it comes in the sizes of 90, 105 and 125. Max. pumping volume is about 100 m³/h. Pressure difference is up to 50 bar.