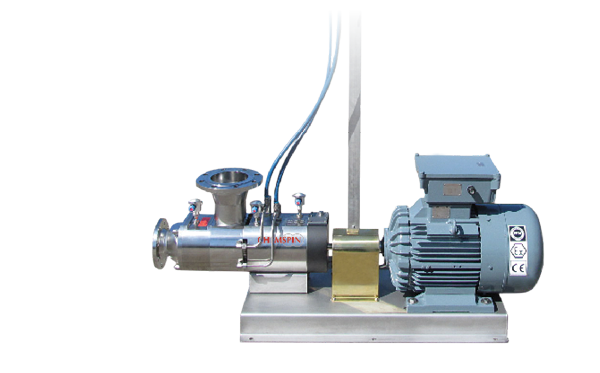

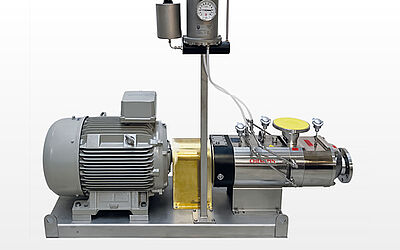

CHEMSPIN ATEX – flexible, universal, and safe

CHEMSPIN twin-screw pumps can also be used in ATEX Zones 1, 2, 21, and 22. Hereby, and depending on pumping temperature, temperature classes T2 to T4 can be realised. The contact-free conveying principle is of advantage here. Also the CHEMSPIN ES with lengthened screws is available as an ATEX version.

Hereby, the ATEX concept consists of the following measures:

• Use of flameproof enclosed motors for speed control

• Surface temperature monitoring with sensors on pump housing and bearing supports

• Maintaining seal temperatures by means of a monitored flushing system for double-acting floating ring seals

• Dry running is prevented by monitoring with single-acting floating ring seals

• Non-failsafe couplings or spark suppression using couplings in an oil bath

• Non-sparking contact protection for base plate devices

• Earthing connections for equipotential bonding

Dry-run safe units with corresponding shaft seals can be supplied.

You have questions?

We will be happy to advise you.

+49 4101 80409-0

sales[at]jung-process-systems.de

QUICK REQUEST

Consulting:

Henning Grönwoldt-Hesse